Thermal Deburring and Finishing Solutions

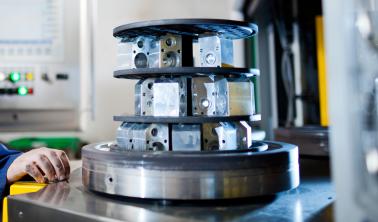

IHL can deburr your finished components using its Thermal Deburring Machine. The Thermal Energy Method of deburring (TEM) is a unique process by which all potentially loose burrs, flash, swarf, whiskers and unwanted particles are guaranteed to be completely removed.

After components have been deburred in the TEM machine, they will be washed in the DURR Ecoclean Cleaning machine to remove the oxide residue and leave a passivated protective surface treatment.

IHL is also able to offer other surface treatment options such as anodising, zinc plating, and etch priming.